Properties of coarse aggregate

when the size of aggregate is >4.75mm,upto 80mm then is known as coarse aggregate.

1. size of aggregate -

generally the maximum size of aggregate is mostly used for construction because its specific surface area is lesser and hence less quantity of mortar is required for lubricating so increases its workability and strength. but

in case of smaller size of aggregate its specific surface area of aggregate is more and then more mortar is required for lubricating and hence its workability is low and also reduces strength of concrete.

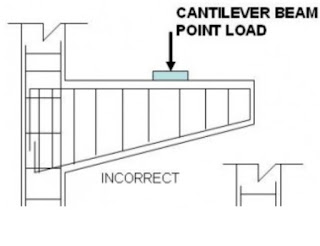

larger size of aggregate is used but is also limited, it depends on following factor-

a. spacing between reinforcement.

b. thickness of cover.

c. mixing & placing technique.

generally , aggregate preffers less than spacing at least 5mm.

if very larger size of aggregate is used then it creats blocking and hence reduction in strength.

2. shape of aggregate -

the shape of aggregate mostly affects the strength of concrete

the irregular shape of aggregate is mostly used for construction because it makes strong bonding with mortar and increases strength, but its workability is low.

rounded shape of aggregate is not preffered because it does not make strong bonding with mortar,its surface is smooth and hence its workability is high.

3. spacific gravity of aggregate -

first of all aggregate is heated at 100°C approx. so that it dries completely. Now it is weighted and same volume of water is taken and compare with eachother , is called as spacific gravity of aggregate.

the spacific gravity of standard aggregate lies between 2.6-2.8

if value is lesser than this value then those type of aggregate is not preffered. only preffered those aggregate which lies in above values.

4. surface texture of aggregate -

surface texture means, surface of aggregate. for good quality of aggregate the surface should be rough and hard so that it makes strong bond with mortar easily and hence more strength.

5. soundness of aggregate -

when the aggregate resists the environmental impact like drying and wetting process, freezing and thawing, acid etc.

then is known as soundness of aggregate.

good quality of aggregate should be sound.

6. Fineness moudulus of aggregate -

fineness modulus is an imperical value which repressents the presence maximum average size of aggregate.

the fineness modulus for standard aggregate is 5.5 - 8

this value is determined by sieve analysis, following sieve is used for fineness modulus-

80 , 40 , 20 , 10 , 4.75 , 2.36 , 1.18 , 0.6 , 0.3 , 0.15 (all in 'mm')

1. size of aggregate -

generally the maximum size of aggregate is mostly used for construction because its specific surface area is lesser and hence less quantity of mortar is required for lubricating so increases its workability and strength. but

in case of smaller size of aggregate its specific surface area of aggregate is more and then more mortar is required for lubricating and hence its workability is low and also reduces strength of concrete.

larger size of aggregate is used but is also limited, it depends on following factor-

a. spacing between reinforcement.

b. thickness of cover.

c. mixing & placing technique.

generally , aggregate preffers less than spacing at least 5mm.

if very larger size of aggregate is used then it creats blocking and hence reduction in strength.

|

| aggregate depends on reinforcement cover spacing |

2. shape of aggregate -

the shape of aggregate mostly affects the strength of concrete

the irregular shape of aggregate is mostly used for construction because it makes strong bonding with mortar and increases strength, but its workability is low.

rounded shape of aggregate is not preffered because it does not make strong bonding with mortar,its surface is smooth and hence its workability is high.

3. spacific gravity of aggregate -

first of all aggregate is heated at 100°C approx. so that it dries completely. Now it is weighted and same volume of water is taken and compare with eachother , is called as spacific gravity of aggregate.

the spacific gravity of standard aggregate lies between 2.6-2.8

if value is lesser than this value then those type of aggregate is not preffered. only preffered those aggregate which lies in above values.

4. surface texture of aggregate -

surface texture means, surface of aggregate. for good quality of aggregate the surface should be rough and hard so that it makes strong bond with mortar easily and hence more strength.

5. soundness of aggregate -

when the aggregate resists the environmental impact like drying and wetting process, freezing and thawing, acid etc.

then is known as soundness of aggregate.

good quality of aggregate should be sound.

6. Fineness moudulus of aggregate -

fineness modulus is an imperical value which repressents the presence maximum average size of aggregate.

the fineness modulus for standard aggregate is 5.5 - 8

this value is determined by sieve analysis, following sieve is used for fineness modulus-

80 , 40 , 20 , 10 , 4.75 , 2.36 , 1.18 , 0.6 , 0.3 , 0.15 (all in 'mm')

|

| different size of sieve: |

Comments

Post a Comment